|

The Buildings

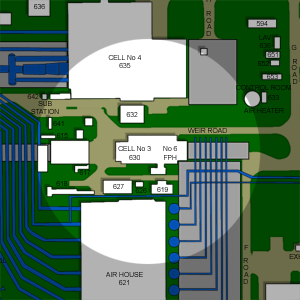

home | the buildings | cell 3 (630)

Cell 3 (630)

Built: 1961

Decommissioned: 2002

Cell 3 was the first testing cell built after plans in the early 1950s to expand

the initial capacity of the site. Constructed at the same time as the Air House,

it was designed as a general purpose cell to provide greater capacity than Cell 2

e.g. it could cater for the new larger engines with their improved performance, and

could simulate higher altitudes, all within a wider range of engine entry temperatures.

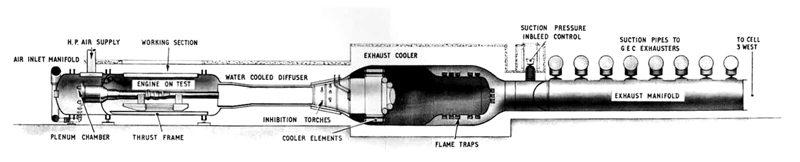

The cell was 138 feet long. The working section, where the gas turbine under test was connected,

was 56 feet long, the diffusing section (where hot exhaust gases were rapidly cooled) was 64 foot long,

the cooler and frame trap sections were 90 foot long with the rest of the length comprising the

connection to the suction mains manifold. The diameters of these components was also impressive

with the working section having a diameter of 20 foot, with a removable section in the roof, and

the diameters of the diffuser and cooler sections were 10 foot and 30 foot respectively.

Such a structure should've had a major presence, easily dwarfing the size of

Cells 1 and 2 which it replaced. But to reduce unwanted emitted noise,

the whole structure was submerged below ground level in a concrete trench. Therefore there was

little outward appearance of this complicated engineering installation.

|

Cell 3, north western corner, as seen from Weir Road.

24|03|07 © Simon Cornwell 2007

|

Two buildings were constructed on top of this trench. The first was the main cell building which

covered the working section. This steel framed building was typical of the austere, functional

buildings of Pyestock. It was shuttered at its western end to allow gas turbines

to be winched into the loading bay and then lowered in a well which contained the working section.

The northern side was clad with glass to increase the natural lighting, whilst brick appendages

on the north and south sides provided space for workshops, storage space and control rooms for icing

tests.

A second building was constructed over another well which gave access to the exterior of the exhaust manifold.

This was little more than a metal frame with steel cladding over its northern and southern sides.

The main control room for the cell was housed in the Computer Building

over 700 meters away. A tunnel, called Monks Passage,

was constructed to provide a connection path between the control room and its cell.

|

General view west across the whole of main external building of Cell 3.

24|06|06 © Simon Cornwell 2007

|

The cell was connected to the new air main and suction mains which were constructed along with the

Air House. It used the Air House (and later the

Parsons No. 9 and

No. 10 exhausters) to produce altitude conditions (unlike

Cells 1 and 2 which were driven by the ejectors). Compressed air was supplied by the

Air House only, whilst exhausting conditions could be produced by all the plant.

It could simulate altitude conditions to 70,000 ft. at mach 2.2, with temperature ranging from -70 through to

250 degrees.

|

|

Cross-section of Cell 3 test plant

|

Temperature control was achieved by a separate heating plant (since removed), a separate cold air plant

(produced by a pre-cooler and pressure dryer system housed in a neighbouring building) and ice making

facilities (which could be found in the Cell 3 building). The four fuel systems connected to

the cell could also be varied and set to different temperatures and pressures. Additionally the GEC sets

could be configured to draw air through the Ceca Air Drying Plant

so tests could be conducted with dry air.

|

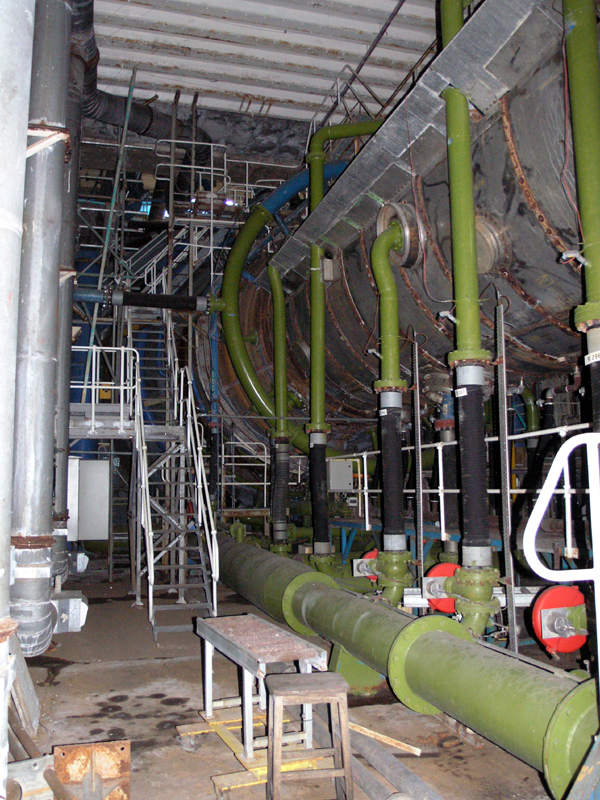

Piping and connections for the water cooled diffuser section. Looking west.

24|06|06 © Simon Cornwell 2006

|

Cell 3 became one of the most used cells of the site, its positioning within the air and

suction mains allowing a plethora of different connection strategies and options. Initially designed

for testing large diameter engines and combat jet testing, it was later used for military engine testing.

It could also be used for steady state performance measurement, control system evaluation, altitude

relighting, the limits of combustion stability, the evaluation of engine performance in severe

icing conditions and the tolerance to distorted inlet flows.

It only closed in 2002 when it was determined obsolete after over forty years of service. But its

working life wasn’t quite over and the working section was dressed up for the feature film Sahara

where the cell doubled-up as part of a futuristic toxic waste disposal facility.

Cell 3 Walkthrough...

Further Reading

|