The Buildings

home | the buildings | plant house (572) | archive pictures

Just found the site which brought back many fond memeories for me. Turbine testing was not the only work undertaken at

Pyestock. I was a civilian Scientific Officer serving in the Royal Naval Scientific Service at the Admiralty

Engineering Laboratory at West Drayton in 1976 when we started transferring diesel test work to Pyestock

as part of defence rationalisation.

I worked in the Plant House until I left the MoD in 1985 and in my 9 years there helped set up and

run diesel engine development tests in C1, C2 and C5 cubicles. I also had a test rig on the old site. Some of your photos show

'my' old (very noisy) office which looked out over Cells 1 & 2. The photo of the walkway along

the C side shows not much had changed in the 22 years after I left.

We undertook development of the diesels for the UK's last diesel electric submarine, the Upholder Class, in addition to other

work for submarines and surface ships. I see from the photos taken in 2007 that all traces of the facilites I used in the cubicles

has been removed. If you are interested I have some photographs showing these circa 1980.

Thanks for helping preserve fond merories. - Mike

|

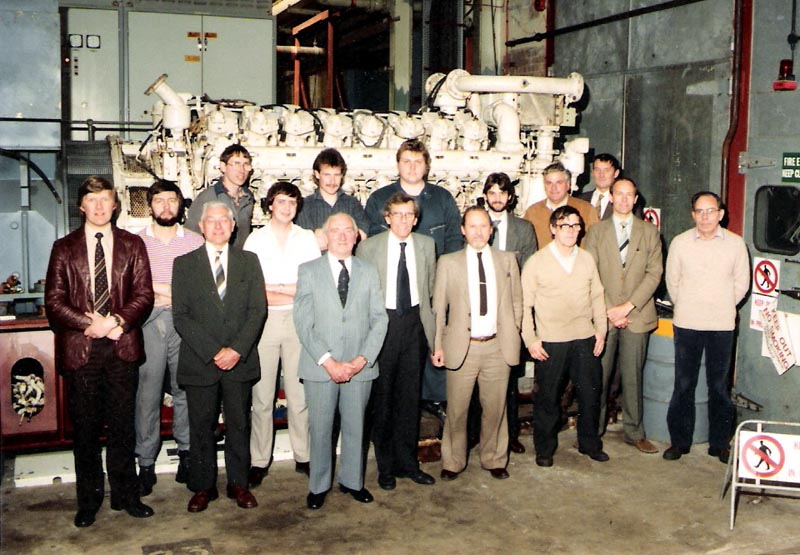

Diesel Test Group with first prototype submarine engine in C5.

© Mike 1985

|

The group photo was taken circa 1985 (I'm at the far left). It shows the whole of the Plant House Diesel Test Team

standing in front of the first prototype Paxman submarine diesel engine that had been installed in C5 cubicle.

The boss (Cdr. Chris Furse) is at the back on the right.

|

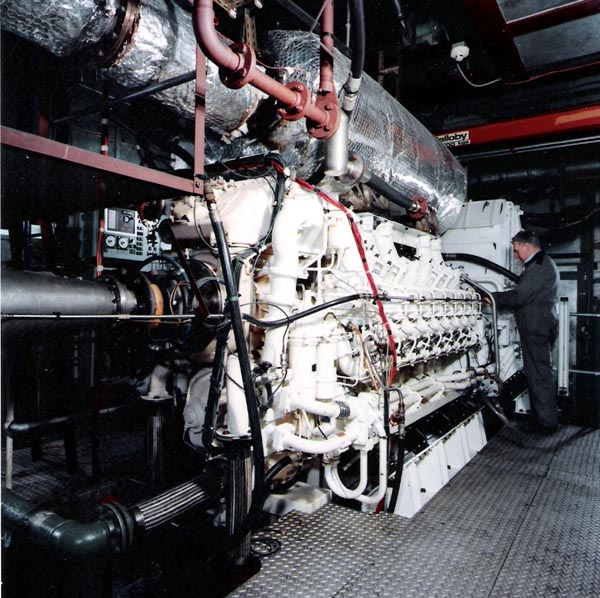

Prototype submarine engine in C5.

© Mike 1985

|

This colour picture shows the inside of the C5 test cell with the submarine engine.

|

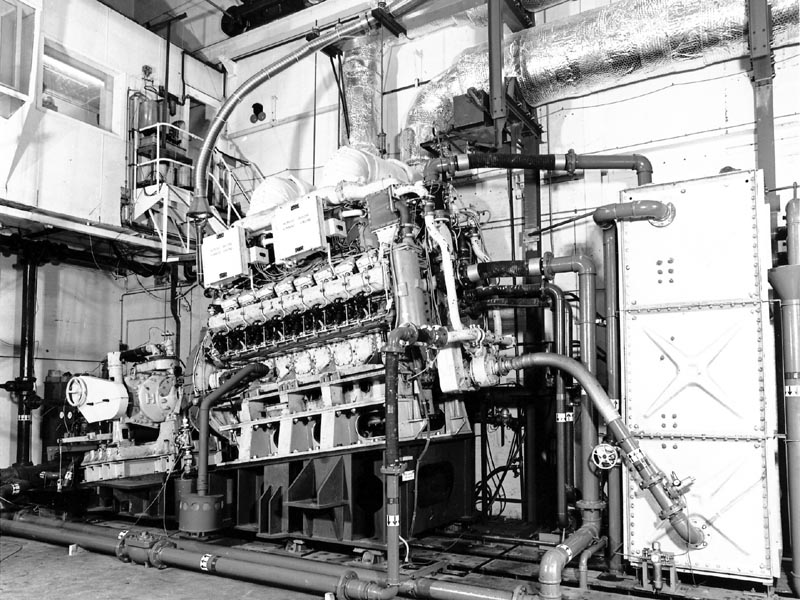

Submarine exhaust water flood test in C5.

© Mike 1985

|

The engine was installed in C5 and set up to simulate operatation in a submarine. The exhaust system was routed outside the

building up into a water tank mounted on top of a scaffold to replicate sea level when dived.

The exhaust was flooded and tests on engine starting and running conducted to enable engine control systems

to be set up for a submarine charging its batteries when dived ("snorting").

|

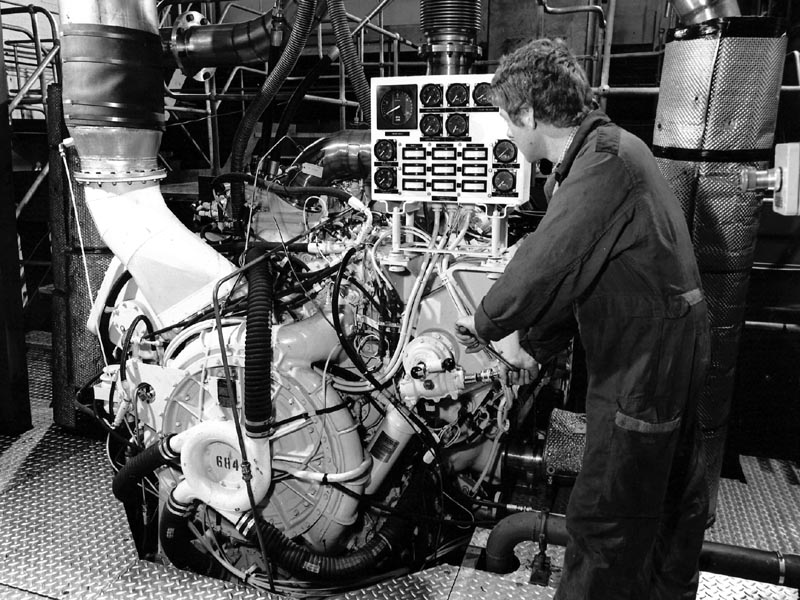

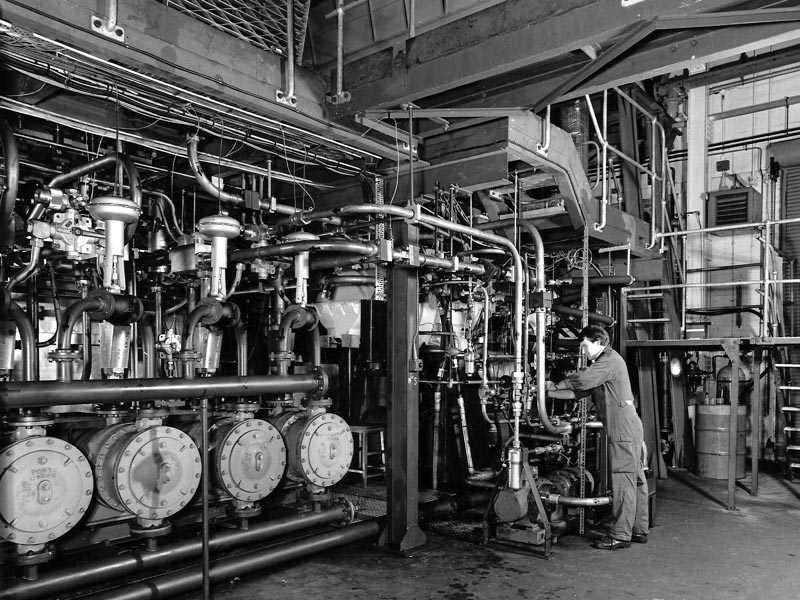

Paxman engine on test in C2.

© Mike 1985

|

A Paxman diesel mounted at an angle (to simulate installation as a marine power unit) in C2 cubicle the Plant House circa 1977.

I controlled testing of this engine through to the early 80's.

|

Deltic Minesweeper engine in C5.

© Mike 1985

|

A Deltic minesweeper diesel in C5 cubicle (being 'barred over' by hand prior to start) - still in use at sea today.

|

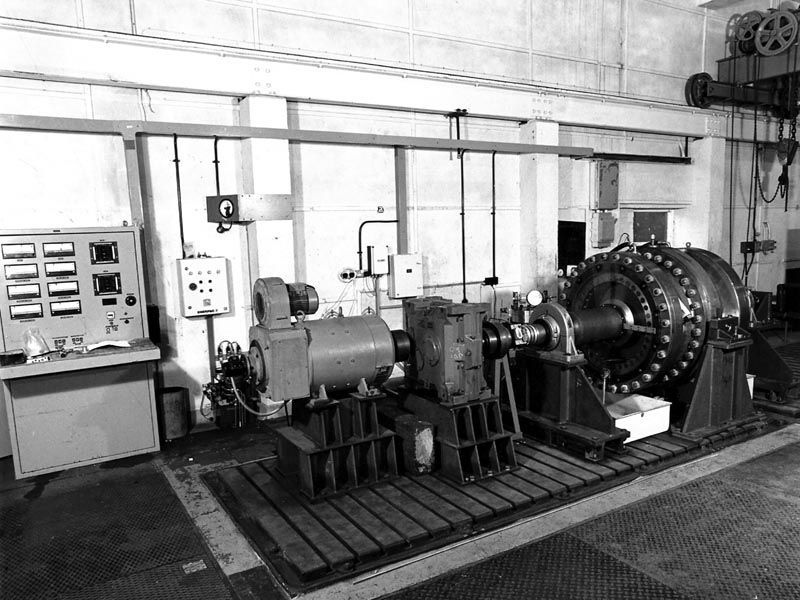

Hydraulic power absorption system in C5.

© Mike 1985

|

The hydraulic power absorption system set up in C5 to take the power from the Deltic engine - it was

driving hydraulic pumps which on the minesweeper gave good low speed control characteristics (essential when hunting mines).

|

Submarine stern seal test rig installed in Old Site test cell.

© Mike 1985

|

A submarine stern seal test rig was set up down on the old site. This enabled the propellor shaft seal to be developed

at simulated deep dive depths. Excessive leakage was not good! I don't know how true, but I was told at the time

(~1980) that the test cell was one which Frank Whittle's team had used many years previously.

|